A Complete Guide to Rare Earth Magnets

Neodymium Rare Earth Magnets

What Is a Rare Earth Magnet?

A rare earth magnet is a magnet made from one of the rare earth elements (of which there are 17) in the Lanthanide series of metals in the periodic table. The two most common rare earth magnets are Neodymium (Nd-Fe-B) and Samarium Cobalt (SmCo). Read more about these two types of magnets.

The term “rare earth” can be misleading, because rare earth metals are not very rare. They’re actually relatively abundant in the Earth’s crust, and the most common ones are found in concentrations similar to commonplace industrial metals such as tine, copper, and zinc. They’re called “rare earth” since they aren’t found in large, concentrated amounts. Rather, they’re mixed in with other elements, making them economically challenging to mine. As a result, only a few sources provide most of the world’s supply of rare earth elements.

By far, China is the world’s largest producer of rare earth metals, with a yearly production of 140,000 metric tons (MT). The US is the next largest producer, with an annual output of just 38,000 MT. The only US mine is the Mountain Pass mine in California. Even though the US is the second-largest producer, the US still heavily imports rare earth materials and metals since the output isn’t plentiful. In contrast to China, Vietnam and Brazil are the 9th and 10th largest producers with 1000 MT each.

Rare earth magnets are the strongest permanent magnets available and have significantly higher performance than ceramic/ferrite magnets (composed of strontium carbonate and iron oxide) and alnico magnets (composed of aluminum, nickel and cobalt).

How Rare Earth Magnets Are Separated

Since rare earth elements are found among other elements, they must be separated using a solvent extraction process. This process involves performing a chemical reaction to force one of the two elements to change phases (for example, going from a liquid to a solid). When this chemical reaction happens, the elements separate, and the concentrations of elements change. However, the change is minor, so it takes thousands and thousands of extractions to get to a purified phase. As a result, while the process works well, it’s a very inefficient and time-consuming process that produces a huge amount of waste.

Watch this video to learn more.

Neodymium and Samarium Cobalt : The Two Most Common Types of Rare Earth Magnets

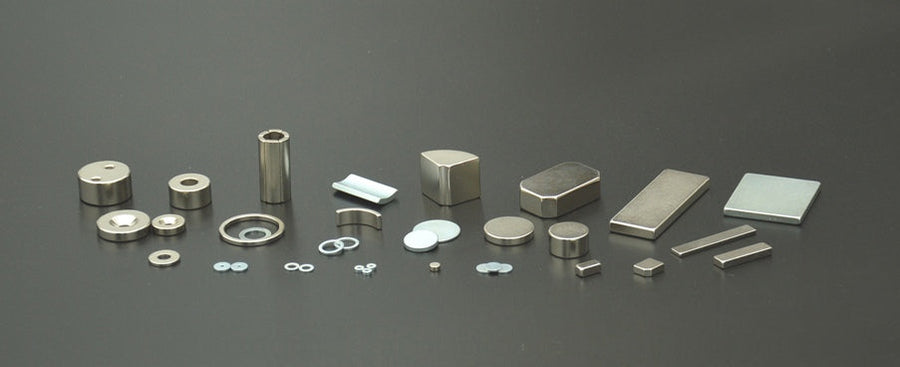

Neodymium (Nd-Fe-B) and Samarium Cobalt (SmCo) are the two most common types of rare earth magnet materials. Since they both come from the same series of metals, they have similar properties and crystal structures. Both types are extremely strong, and they tend to be brittle.

As described in the What Is a Rare Earth Magnet section, rare earth magnets are mined along with other elements, so they’re not pure elements. Neo magnets are composed primarily of neodymium, boron and iron, and samarium cobalt is composed of samarium and cobalt.

Both materials come in different grades, or strengths, and have different magnetic and physical properties. Check out our magnet comparison chart for product details.

These magnets tend to be brittle and are vulnerable to corrosion. Manufacturers typically nickel-plate the material to protect it from oxidation.

Neodymium and Samarium Cobalt Magnet Attributes

Neodymium and samarium magnets have several advantages and disadvantages.

Neodymium

Samarium

Strongest Magnet Material on the Market Today

(stronger than samarium)

(stronger than samarium)

Energy

High Coercive Force (Resistance to Demagnetization)

High Temperature Stability

Low Mechanical Strength (Brittle)

Moderate Temperature Stability*

Low Corrosion Resistance

Higher Cost

(Moderately)

(Moderately)

*Depending on grade

Definitions

Coercive Force, Hc

The amount of force, as measured by Oersteds, required to reduce the magnetization of a permanent magnet to zero. Some types of magnets, ceramic for example, are more easily demagnetized than others.

Demagnetization Force

A force, which is the opposite direction of the field of a magnet, which removes the flux of a magnet after it has been fully magnetized.

Mechanical Strength

The amount of strength a material has to withstand an applied load.

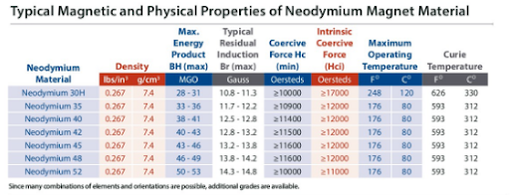

Here are some magnetic and physical properties of neodymium magnet material.

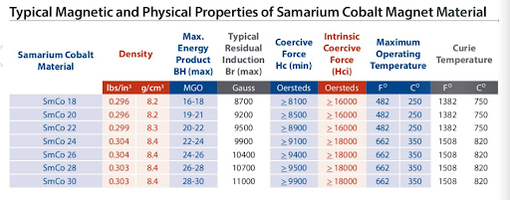

Here are some magnetic and physical properties of samarium cobalt magnet material.

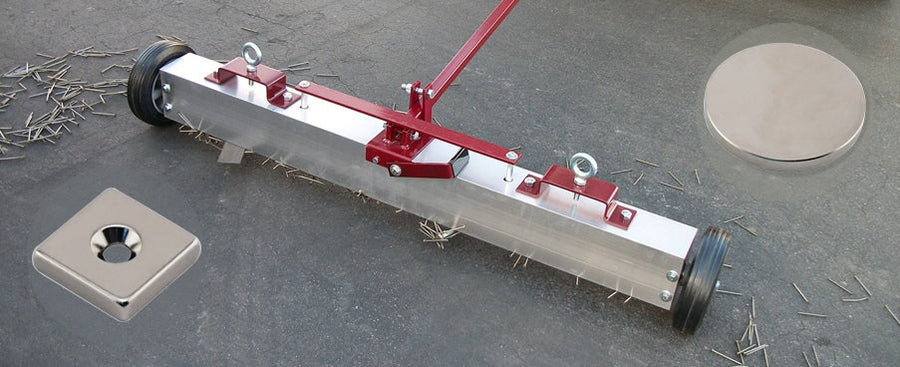

Neodymium Applications

Neodymium magnets are used in all kinds of applications for business and consumer purposes.

Here are a few common examples.

Business

- Magnetic separators

- Linear actuators

- Microphone assemblies

- Servo motors

- DC motors (automotive starters)

- Computer rigid disc drives, printers and speakers

- Medical devices

- Traveling wave tubes

- Satellite systems

Consumer

- Lifting magnets for automotive

- Garage applications

- Home projects

- Door locks

- Crafts

Samarium Cobalt Applications

Samarium magnets are used in all kinds of applications for business and consumer purposes.

Here are a few common examples.

Business

- Technology such as computer disc drives and sensors

- Traveling wave tubes

- Linear actuators and satellite systems

- Motors where temperature stability is vital or extreme

- Aerospace

- Defense systems

Consumer

- Lifting magnets for automotive

- Garage applications

- Home projects

- Door locks

We’re dedicated to helping you choose the correct magnet for your application. If you’re not sure how to select a magnet or can’t find what you’re interested in, contact us for help. We also provide custom solutions, and we’d be happy to help find what’s best for your project.

Choosing the Right Magnet for Your Application

From a business need to a home project, you could have a wide (or slim) range of requirements for a magnet. Don’t feel like you’re alone in your decision-making though - we’re always here to help you!

Here are some things to consider:

- What type of application is it? Do you need a magnet to hold something in place? To organize an area? Or a specific application for a manufacturing floor?

- How strong of a magnet do you need? You may need something that can do more (or less) than you think.

- Will you have any special temperature requirements? Will the magnet be in the hot sun all day or in a refrigerated compartment?

- What’s the space like? Is it tight? Large? Heavily trafficked?

- What shape do you need? A block? Tube? Latch?

You may have other considerations as well, and we can help you with finishes, grades and pull ratings.

With so many magnet options, it can be a challenge to know which magnet is right for your project. Contact us, and we can help! Feel free to send us a picture, sketch or drawings of the drawings or the area, and any other information you have.

With over 20 million magnets for sale, we’ve got you covered! But don’t worry – that’s why we’re here. We truly enjoy helping customers find the right magnet. You can take several paths to find the right solution:

- On our home page, you can search by who you are (a business or a consumer), magnet type, pull force, application and more.

- Read our Choosing the Right Magnet page to ask yourself some questions about your magnet type.

- Search our product catalogs to get ideas about your project and things you can do with magnets.

Contact Us

Customers rely on our team of magnet experts who guide product design, magnet material and technology, engineering, development, production and more.

Safety and Handling

Rare earth magnets are safe to handle as long as you use common sense and respect. Here are brief magnet safety tips to prevent injury and property damage.

- Wear gloves and protective eye gear when handling magnets.

- Don’t allow children or pets to play with magnets.

- If magnets are swallowed, call 9-1-1 immediately.

- For those with nickel allergies, avoid prolonged handling of these magnets.

- Avoid placing magnets near older electronics that store information.

- Follow proper packing and shielding guidelines when shipping magnets by air, as magnets affect compasses and navigational equipment. Read our Shipping Magnets: Understanding the Rules page for more information about shipping.

- Magnets can interfere with medical devices such as pacemakers, magnetic ports and other equipment. Avoid handling magnets near the medical device.

- Properly store and label magnets.

- To separate magnets, slide the magnets instead of pulling them apart.

- Don’t drill, sand or machine-alter neodymium magnets as their powder and dust are highly flammable and can spontaneously combust.

- Don’t expose magnets to temperatures higher than their maximum operating temperatures, as magnets can become demagnetized.

If you have any questions or concerns, our Magnet Experts are here to help.

For more information, read our Handle with Care: Tips for Magnet Safety page.

FAQs

1. What are rare earth magnets?

Rare earth magnets come from one of the elements in the Lanthanide series of metals in the periodic table. The two most common rare earth magnets are Neodymium (Nd-Fe-B) and Samarium Cobalt (SmCo). Since these two magnets come from the same series of metals, they have similar properties, but they’re also different.

2. Why are they called “rare earth” magnets?

Rare earth magnets actually aren’t rare in terms of the amount of elements present in the Earth’s crust. They’re rare in that they are typically found dispersed with other elements and not in large, concentrated areas. Due to the way they’re found in the Earth’s crust, mining rare earth elements can be economically challenging.

3. What are neodymium magnets?

Neodymium magnets, also known as neo magnets, are part of the rare earth family of magnets. They’re known for their extreme strength for their size (they’re the strongest magnet) and a high coercive force.

4. What can I use neodymium magnets for?

Neodyumium magnets are used in many different industries, including technology, manufacturing, automotive, healthcare and more. They can also be used for home applications. Learn more about neodymium magnets for sale.

5. How strong are neodymium magnets?

Neodymium magnets are the strongest magnets available! The strength of a magnetic field is measured in BHmax (maximum energy product). The higher the BHmax, the higher the strength. For example, a samarium magnet has a BHmax of 24, and a neodymium magnet has a BHmax of 40.

6. Where can I buy neodymium magnets?

We sell thousands of neodymium magnets with a wide range of specifications to meet business and consumer needs. Our neo magnets come in different grades, shapes and sizes.

Check out our magnet materials guide to compare neo, samarium and other magnets that we sell. We want to help you choose the right magnet for your application.

Also, feel free to contact us for help. We can discuss your needs and point you in the right direction. We can also provide custom solutions.

7. How can I order neodymium magnets?

You can order neodymium magnets through our website. You can also call us at +1.866.867.0941 or email us at weblead@magnetsource.com. We’re happy to help you find the right solution.

8. What makes neodymium magnets unique?

Neodymium magnets are unique because of their strength – they’re the strongest magnets available. In addition, they have a high coercive rate (meaning they have a high resistance to demagnetization).