- Rectangular and Cuboid: Often used in applications where space is constrained, such as in small motors or sensors.

- Cylindrical and Disc: Ideal for applications requiring a uniform magnetic field, such as in magnetic sensors or small motors. The cylindrical shape also facilitates the use of alnico magnets in rotary applications.

- Ring: Often used in magnetic assemblies where the magnet needs to encircle a component or create a magnetic field in a cylindrical space. Common in applications like magnetic couplings and rotor assemblies.

-

Horseshoe: Provides a concentrated magnetic field between the poles, making it suitable for applications such as magnetic holders or clamping devices.

- Custom Geometric Shapes: Cast alnico magnets can be customized into complex shapes to meet specific design needs, such as in automotive ignition systems, where unique geometries are required for optimal performance.

FEATURED POST

Get Premium Alnico Magnets for Automotive Applications

The Many Applications and Advantages of Alnico Magnets in the Automotive Industry

Manufacturers in the automotive sector use permanent magnets to produce durable vehicle parts, components, and systems. These magnets help improve engine efficiency, enhance vehicle safety, and maintain vehicle performance.

Alnico magnets in particular offer a unique combination of strength and stability, making them suitable for the industry's distinct needs. These magnets remain reliable in demanding environments, making their application in the motor industry invaluable.

Alnico Magnet Types and Properties

Alnico magnets exist in two broad categories based on their manufacturing process:

Sintered Alnico Magnets

Sintered alnico magnets are manufactured by compressing alnico powder and other ingredients using a pressing machine. The compacted powder is then sintered into strong alnico magnets in a process that allows for precise control over the composition and microstructure of the magnets.

Powder metallurgy is the process used in the manufacturing of sintered alnico magnets that enables the production of magnets with complex shapes, and ensures uniform distribution of elements, and minimizes material waste.

Sintered alnico magnets are ideal for applications where consistency and reliability are crucial. They maintain strong magnetic properties over a wide range of temperatures, ensuring dependable performance in critical components. Sintered alnico magnets are suitable for sensors, electric motors, and ignition systems in the automotive industry.

Cast Alnico Magnets

Cast alnico magnets are made by casting molten metal alloys into molds. This process allows for the production of magnets in various geometric shapes to fit specific design requirements in the automotive industry. Typical shapes of cast alnico magnets include:

The Many Applications of Alnico Magnets in the Automotive Industry

Alnico magnets are valuable to the automotive industry in various ways:

Sensors

Alnico magnets are suitable for sensors because of their ability to maintain magnetic properties over a broad temperature range, ensuring consistent performance in varying environmental conditions. They are also resistant to demagnetization, ensuring long-term accuracy and reliability of sensors. These permanent magnets are ideal for speed, position, and magnetic field sensors in the automotive industry.

Electric Motors

Alnico magnets offer consistent magnetic strength and stability, crucial for the reliable operation of electric motors. Their high coercivity provides a strong and stable magnetic field necessary for achieving quick and efficient starts in starter motors. The electric vehicle industry benefits from alnico magnets' combination of strength and lightweight properties, which is essential for electric and hybrid vehicles where reducing weight can significantly impact overall vehicle efficiency and range.

Ignition Systems

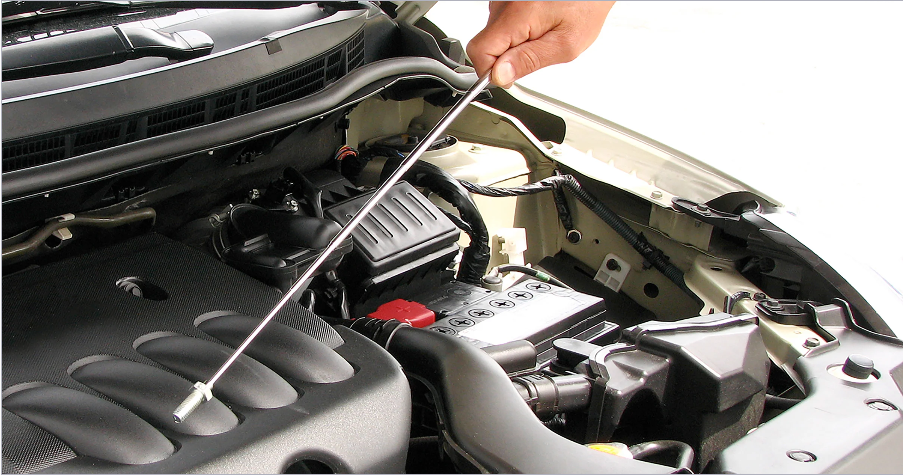

Alnico magnets are used in ignition coils and magnetos to create a consistent magnetic field necessary for inducing high voltage in the coil windings, which is then used to produce a spark. Ignition systems also benefit from these magnets due to their ability to maintain magnetic strength even at high temperatures. The consistent magnetic fields produced by alnico magnets enhance accurate timing in distributor rotors and stators.

Audio Systems

Alnico magnets' superior magnetic properties make them valuable in the manufacturing of car speakers, including woofers, tweeters, and midrange drivers. They offer a stable magnetic field required to drive the speaker's voice coil effectively. Alnico magnets' ability to maintain magnetic properties under high temperatures and varying conditions helps minimize harmonic distortion and improve overall sound quality in car speakers.

The Many Advantages of Alnico Magnets in Automotive Applications

Manufacturers in the automotive sector benefit from the unique properties of alnico magnets in various ways:

Performance Under Extreme Conditions

Alnico magnets maintain their magnetic properties even in extreme temperatures, making them valuable in manufacturing automotive parts. They are renowned for their consistency in extreme temperatures, whether from engine heat, external weather conditions, or other factors. These magnets operate effectively in both extremely hot and cold environments. Alnico magnets' robust physical properties make them ideal for parts used in automobiles subjected to significant mechanical stress and vibration. They comfortably resist demagnetization despite the shocks encountered during operation.

Resistance to Corrosion

The alloy ingredients and production processes of alnico magnets make them inherently resistant to corrosion. The stable chemical properties of aluminum, nickel, and cobalt make these magnets less prone to oxidation compared to other metals, making them useful in situations that expose them to moisture and oxygen.

Long Service Life and Reduced Maintenance Needs

Alnico magnets maintain their potency for a long time, making automobile parts durable and reliable. This longevity helps manufacturers in the automotive sector retain clients, enhance brand trust, and reduce cases of product recalls due to faulty parts.

Order Premium Alnico Magnets for Your Automotive Needs

Alnico magnets' unique properties, such as high coercivity, resistance to extreme temperatures, and inherent corrosion resistance, make them an ideal choice for various automotive components and systems. Manufacturers in this industry value these permanent magnets' versatility and robustness, making them a key material in automotive engineering.

Are you looking for reliable and high-performance alnico magnets for your automotive applications? Master Magnetics offers a wide range of alnico magnets designed to meet the demanding needs of the automotive industry. Explore our selection today and discover how we can help you achieve exceptional performance and durability in your vehicle components.